| Sign In | Join Free | My gimpguru.org |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My gimpguru.org |

|

Brand Name : BEISU

Model Number : BS-800

Certification : CE

Place of Origin : CHINA

MOQ : 1 set

Price : Negotiable

Payment Terms : T/T, L/C

Supply Ability : 2 sets per month

Delivery Time : 90 working days

Packaging Details : Plastic film packing and pellet fix on the bottom

Material : HDPE

Pipe range : 315mm~800mm

Extruder model : SJ-150/33

Max. output : 800kg/h

Max.speed : 1.5m/min

Warranty : 12 Months

Processing type : Extrusion Machine

Automatic grade : PLC

Under ground 315mm~800mm HDPE drainge solid pipe machine extrusion line

Brief introduction of PE pipe production process:

The first step, raw material compounding and drying: PE pellets and water supply pipes are purchased from PE pellets, first mixed with the added masterbatch and antistatic masterbatch (gas tube) in the mixing mixer. After uniformity, the uniformly mixed material is pumped into a storage tank having a heating and drying function by a suction machine.

The second step, the plasticizer extrusion molding of the extruder: the extruder screw barrel and the molding die are electrically heated by the externally coated heating ring, and the working temperature is 160-220 °C. The material enters the extruder barrel from the storage hopper, and is conveyed, metered, plasticized, and compressed into the molding die under the conveying and shearing of the spiral rib. A small amount of mixed color strands are heated and plasticized by a small screw extruder to enter from the side of the mold. The two materials are mixed and extruded through a die.

The third step, vacuum setting cooling: the formed material passes through the sizing sleeve into the vacuum cooling box for shaping and pre-cooling, and then after two stages of cooling to cool to normal temperature and complete the shaping process.

The fourth step, printing, drawing, cutting, turning and winding: the shaped pipe is printed, and the length is measured under the traction, and the cutting machine enters the turning frame or the winding machine (for the pipe below DN50), and Cut to the set length.

The fifth step is to inspect the qualified products into the warehouse: the cut products are inspected and the qualified products enter the warehouse. The non-conforming product and the waste scrap produced during the production process are crushed and returned to the production system for reuse.

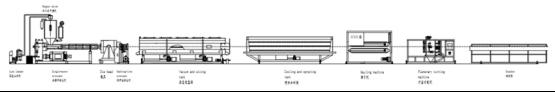

Layout:

Raw material+additive→Mixer→Auto Feeder→Hopper dryer→Single screw Extruder→-Moulds→Vacuum calibration tank→Spray Cooling Tank→Haul-off Unit→Cutting Unit→Stacker

Details specification pictures of HDPE pipe production line by BEISU Machinery:

Main technical parameter:

| Pipe range | 16-63mm | 20-110mm | 75-160mm | 90-250mm | 110-315mm | 160-500mm | 315-630mm | 500-800mm |

| Extruder | 65mm | 65mm | 75mm | 75mm | 90mm | 90mm | 120mm | 150mm |

| Extruder power | 37kw | 56kw | 110kw | 110kw | 160kw | 185kw | 250kw | 335kw |

| Extrusion capacity | 60-kg/h | 100-150kg | 250-300kg | 250-300kg | 350-400kg | 400-500kg | 450-750kg | 750-1000kg |

| Max.production speed | 10m/min | 6m/min | 6m/min | 6m/min | 3m/min | 2m/min | 0.9m/min | 0.7m/min |

Our company has formed a mature product system, plastic extrusion molding equipment: PVC, PP, PP-R, PE, HDPE, double pipe extrusion production line, profile, wood-plastic profile, frame foam, plate (sheet) Material, door panel extrusion production line, waste plastic recycling, cleaning granulation production line, auxiliary equipment: mixing unit, crusher, loading machine, dryer, mold temperature machine, chiller, color mixing machine, vibrating screen, printing machine, milling Machine, traction, cutting machine, etc.

Our company will continue to innovate, work diligently, provide more products to meet the special needs of customers, perfect and strive to be your business partner.

Our company has always been adhering to the corporate philosophy of “Time and space to witness eternal, quality is with you”, constantly pursuing higher quality and better service, so that quality awareness is widely promoted and executed in the enterprise. Everything we do is for Guarantee your customers' most basic interests and create value for you.

|

|

Under Ground HDPE Drainge Solid Pipe Machine 800kg/h Max Output Easy To Operate Images |